- Introduction to EMC Monitoring

- What is the need to monitor the air?

- EMC subsystems

- EMC System types

- IAQ Standards in India: A summary

- CAAQMS

- EMC Monitoring Systems drawbacks

- How modern technology is overcoming EMC Monitoring System drawbacks?

Introduction to EMC Monitoring

EMC, Continuous Emission Monitoring System is a real-time air quality monitoring system. Many industries need systems to measure and monitor a variety of pollutants. EMC is the sum of various activities related to determining and reporting air pollution emissions from sources such as stationary sources. Coal and oil powered power plants, mining activities, cement plants, brick kilns, waste furnaces, chemical waste plants, as well as many chemical process industries need to monitor emissions on a constant basis. Then, the data recorded from emission activities are recorded constantly that can be used by govt. agencies. EMC monitoring systems are used to determine the compliance with stationary sources with their emission limitations.

What is the need to monitor the air?

There are many pollutants that the air carries with it both indoors and outdoors. These pollutants in lower levels can undoubtedly cause discomfort. Whereas if these air pollutants surpass the allowed limits, they are considered very harmful to the human body. With air pollution being one of the top 5 reasons for premature deaths around the globe, indoor air can be 10X more harmful than ambient air pollution. That makes it necessary to monitor the air quality especially indoors. What you can monitor, can be controlled. Therefore, by monitoring the air quality we can control its after-effects on our bodies.

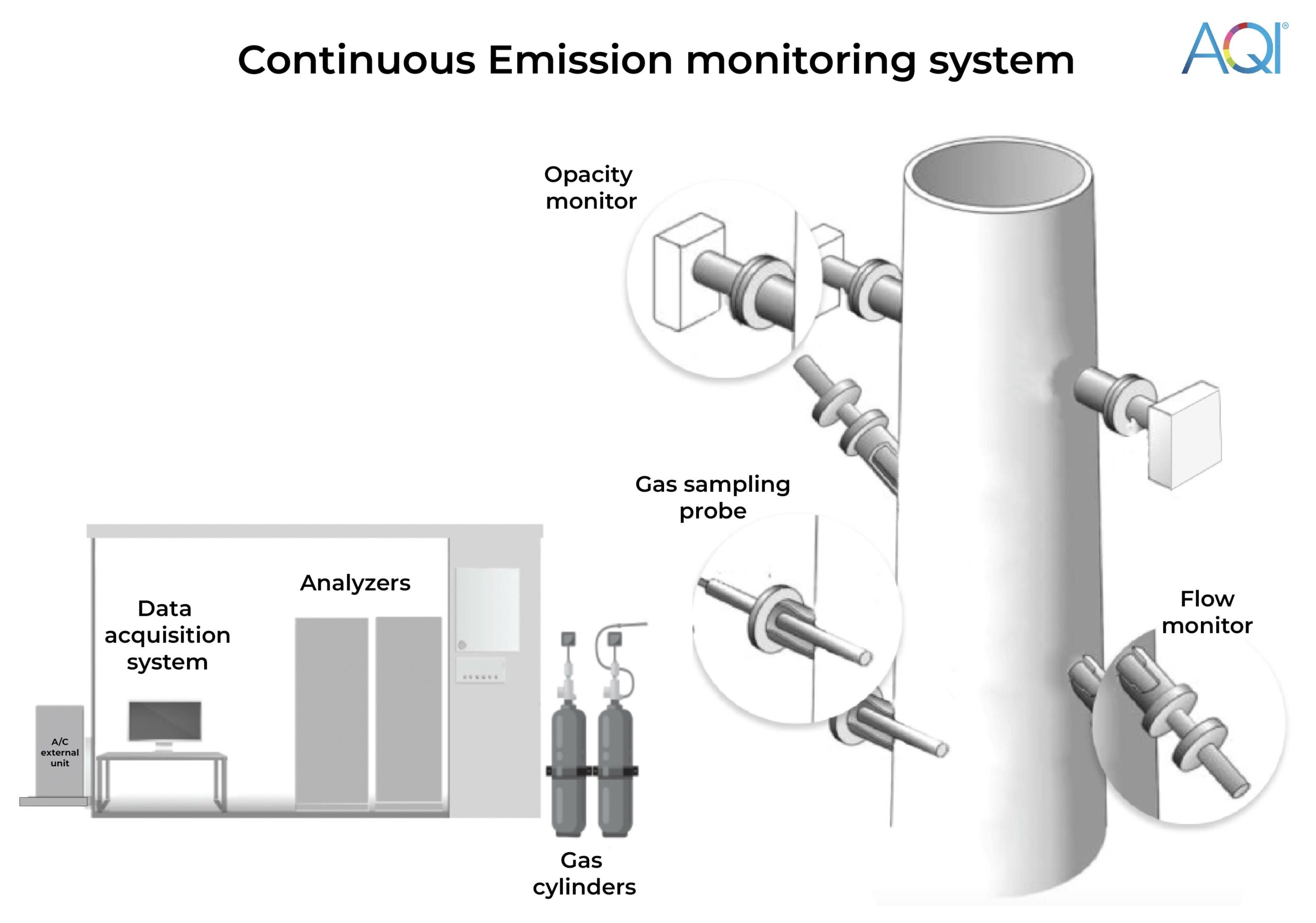

EMC Monitoring Systems and its other sub-systems

The way the interface is designed can be used to describe EMC Monitoring Systems, the following sub-systems make up EMC systems:

- Sampling Interface– a component that either transfers or separates the tester’s flue gas.

- Data acquisition system– Data from the tester is received by the data acquisition system, which then transforms it into the proper units, records it, and generates reports for both internal and external usage.

Today, EMC data gathering systems are routinely networked to engineering, corporate, and even agency offices when the data is used for a range of operational and management objectives.

- Controller system– The controller subsystem is critical to the overall system’s functionality. It is in charge of the system’s automatic functions such as calibration, probe purging, and alarms.

- Gas Testers– The selection of gas testers for an extractive EMC Monitoring System is critical since some analytical techniques are more appropriate in a source application or system architecture than others.

Disadvantage- While it is possible to lower the size of gas testers, given the amount of space available in most industrial sites, there is typically no incentive to re-engineer the equipment.

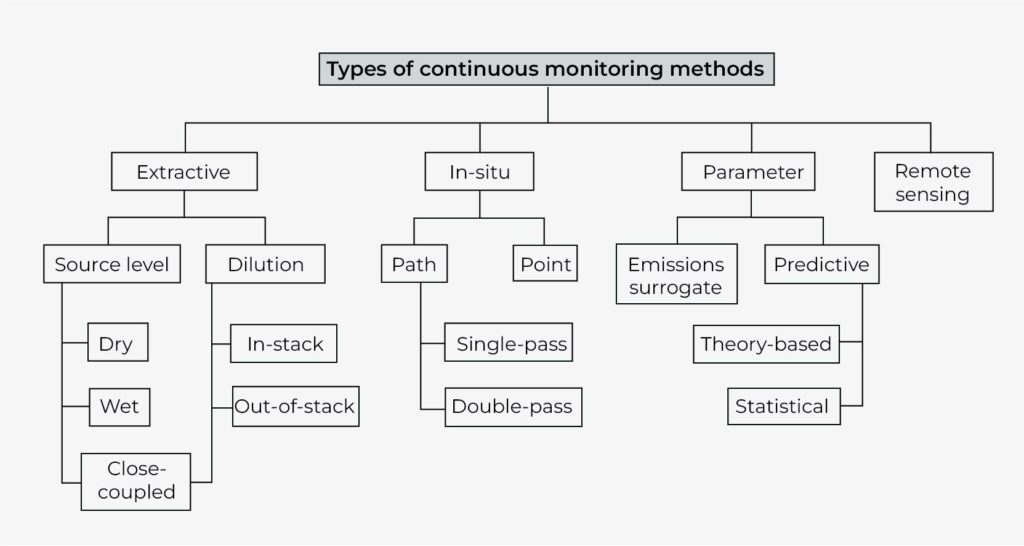

Types of EMC Monitoring Systems

Following are the different types of EMC monitoring systems on the basis of the techniques used, sources and variable conditions.

- Extractive Systems-

In extractive systems, the interface consists of a system that extracts and conditions the gas before entering the testers. This depends on the source levels on the basis of source type, that is wet, dry, or close- coupled.

- In-situ Systems-

The interface in in-situ systems is simpler, consisting of flanges designed to either align or support the monitor and blower systems used to limit PM interference.

-> Both extractive and in-situ technologies operate in the source environment and must operate under changing stack and ambient conditions on a continuous basis, therefore, different techniques have been sought, despite the fact that this is not necessarily a problem for properly built and maintained systems.

Alternative 1: Computerized “predictive emission monitoring systems,” or PEMS, have resulted from the correlation of stack emissions to process variable data.

Alternative 2: Remote sensing has been employed with little success but is not generally used.

- Variable Monitoring Systems-

The variable data is used directly either as a proxy for emissions data based on their levels, or it can be put into a model to forecast emissions. Several regulatory programs have long used variable data to monitor the performance of emission control equipment, such as pressure drop or temperature. Furthermore, the variable data has been utilized as a regulatory trigger to directly launch enforcement action or as an indicator of disagreement with permit requirements.

Hence, a more modern approach has been utilized to create emission models based on the value of process variables.

- Remote sensing-

Other than the outdoor environment, there is no interaction between the stack gases and the sensing device in these systems. As a result, they are not associated with a stack or duct interface. Hence, these devices can determine emission levels either by beaming light up to the stack or monitoring light emitted by the stack’s “hot” molecules.

IAQ Standards in India: A summary

|

Variables |

WHO guideline value (2005) |

ASHRAE Standard 55 |

OSHA 8 hour work shift |

NAAQS and EPA- USA |

|

PM10 |

50µg/m3 (24-hr mean) |

– – |

15mg/m3 (total) |

150µg/m3 (24-hr) |

|

PM2.5 |

25µg/m3 (24-hr mean) |

– – |

5mg/m3(resp.) 6 |

65µg/m3 (24-hr) |

|

SO2 |

20µg/m3 (24-hr mean) |

– – |

5ppm (8-hr) |

140ppb (24-hr) 75ppb (1-yr) |

|

NO2 |

200µg/m3 (1-hr) 40µg/m3(annual mean) |

– – |

5ppm (8-hr) |

53ppb (annual) 100ppb (1-hr) |

|

CO |

10ppm (8-hr) |

9ppm (8-hr) |

50ppm (8-hr) |

9ppm (8-hr) |

|

CO2 |

– – |

1000ppm (8-hr) |

5000ppm |

|

|

Humidity |

– – |

30% – 65% |

– – |

|

|

Temperature |

– – |

68°F – 74.5°F (20-23.6°C)(winter) 73°F – 79F° 22.8-26.1°C)(summer) |

– – |

Continuous Ambient Air Monitoring System

CAAQMS are continuous ambient air quality monitoring systems. They detect and report different pollution variables in the outdoor environment. CAAQMS measures these pollutants using different technologies like BAM. Despite the data provided by these devices being highly accurate, there are several drawbacks to these technologies such as non-portability due to their size, extremely costly (only suitable for govt. agencies), intensive manpower required, complex connectivity, and data accessible through govt. websites, regular filter changes, etc.

Introduction to the modern day CAAQMS was to overcome these drawbacks, while providing accurate and reliable data. These monitors are economical, easy to use, highly portable, light weight, and provide the real-time pollution levels within seconds. Moreover, these do not require any after purchase expenses like filter change, calibrations, etc. Connectivity is quite easy as compared to previously used CAAQMS.

EMC Monitoring System drawbacks:

- For remote sensing systems, performance specification and certification processes have not been defined.

- For in-stack measurements to be valid some concerns must be standardized such as calibration processes, calibration, and accuracy.

- Costs- Subsystems cloning that happens when employing single gas testers raises EMC costs. Therefore, multi-gas approaches are used by manufacturers to save costs.

- Size- EMC are testers that do not operate alone but are part of a bigger system. As a result, their size is notably larger than today’s compact, handy, and portable technology.

- Routine maintenance programs are required to keep systems such as extractive systems, plumbing, and electro-optical systems running.

- There are several usage errors, therefore, more frequent poor performance of EMC systems.

How modern technology can help in air quality monitoring?

Emission limitations are becoming increasingly precise and the proper operation of pollution control equipment are becoming increasingly important. That is why EMC monitoring systems have progressed to the point where they can now meet the most demanding applications.

Alternative techniques to standard monitoring methods have been developed that do not rely on analytical techniques but instead rely on inputs from process sensors. As a result, these sensors‘ data can be used in a variety of ways, including environmental regulation programs, and individual air quality monitors in homes, offices, schools, construction activities, real estate, hospitals, cinema halls, restaurant and hotel industries, and factories. The variable data can also be used immediately to monitor air quality in a variety of applications. The data can further be used to forecast emissions.

Prana Air sensors and air quality monitoring technology are not only compact and portable, but you can easily access the data remotely, that too 24X7. They are discreet and highly affordable as well. Emissions in factories are very harmful for the workers’ health and the emissions should be limited. So, Prana Air AQ solutions will help you in monitoring the emissions both inside and outside factories and power plants. AQI India will provide you with the real-time ambient air quality index as well as the subscription model enables you to see the AQI of indoor areas such as your homes, offices, etc. It will also provide you with a customized dashboard where you can view all your devices.

Also read: Why Monitoring Air Quality data has become an absolute necessity.